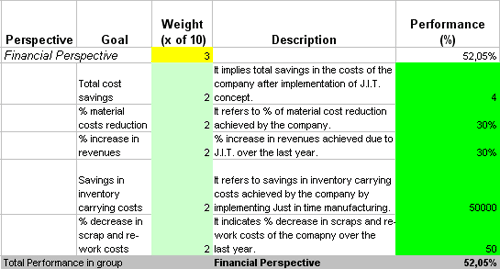

In today-s competitive business environment, quality is not the only thing that matters. Superior quality at minimum costs is what customers demand. To decrease costs, manufacturing firms have to minimize their expenditures in every field. To do so, Just in Time philosophy is just best for them. This philosophy aims at reducing costs by manufacturing and delivering goods in right quantity and at the right time. KPIs can help a lot in determining which processes support Just in time manufacturing.Financial perspective helps to determine the various costs and savings involved in Just in Time Manufacturing processes. It consists of KPIs like total cost savings, % material cost reduction, % increase in revenues, savings in inventory carrying costs and decrease in scrap and re-work costs.Operational Efficiency includes the measures helps in judging the efficiency of manufacturing operations of the company. The KPIs for this perspective are number of on time deliveries, % decrease in scraps and reworks, % increase in productivity and first-pass yield rates.Internal process perspective serves as an effective measure to implement the planning of processes in such a way so as to keep the inventory of raw material, work in progress and finished goods to the minimum. The KPIs are reduction in idle time, % manufacturing cycle time reduction, % increase in inventory turns and % reduction in supplier lead times.Learning and innovation perspective consists of measures that help in evaluation of new techniques and tools used to improve manufacturing processes. It includes KPIs as number of new/automated machines, number of training sessions and number of meetings of workforce and % reduction in new product introduction rate.

In today-s competitive business environment, quality is not the only thing that matters. Superior quality at minimum costs is what customers demand. To decrease costs, manufacturing firms have to minimize their expenditures in every field. To do so, Just in Time philosophy is just best for them. This philosophy aims at reducing costs by manufacturing and delivering goods in right quantity and at the right time. KPIs can help a lot in determining which processes support Just in time manufacturing.Financial perspective helps to determine the various costs and savings involved in Just in Time Manufacturing processes. It consists of KPIs like total cost savings, % material cost reduction, % increase in revenues, savings in inventory carrying costs and decrease in scrap and re-work costs.Operational Efficiency includes the measures helps in judging the efficiency of manufacturing operations of the company. The KPIs for this perspective are number of on time deliveries, % decrease in scraps and reworks, % increase in productivity and first-pass yield rates.Internal process perspective serves as an effective measure to implement the planning of processes in such a way so as to keep the inventory of raw material, work in progress and finished goods to the minimum. The KPIs are reduction in idle time, % manufacturing cycle time reduction, % increase in inventory turns and % reduction in supplier lead times.Learning and innovation perspective consists of measures that help in evaluation of new techniques and tools used to improve manufacturing processes. It includes KPIs as number of new/automated machines, number of training sessions and number of meetings of workforce and % reduction in new product introduction rate.

Read Why do business professionals choose ready-to-use KPIs? to find out the answers to these questions:

Ideally, you need to have a strategy (in a form of a strategy map) before you start thinking about the ways to measure its execution (KPIs). Don't have a strategy map yet? Use free Strategy Map Wizard to create a strategy map for your current business challenges. The wizard will:

The whole process takes on average 6 minutes. Give it a try right now - it's free.

JIT (Just-in-time) is a Japanese concept that aims at minimizing inventory level. The reason underlying this principle is that 'costs borne in carrying and holding inventory' has often been found to eat up the revenues brought from it, thereby reducing the profit margins.

From this stems a unique solution of getting the inputs just when they are needed. This saves the manufacturer of expenses incurred in maintaining inventory level.

Ensuring that JIT manufacturing occurs is possible only with absolutely accurate 'integration of operations' with that of suppliers. Various IT and technological software are used to achieve this.

One can keep a track on the process by framing KPI (Key Performance Indicators) for it in a manner that these are able to reflect the performance of the steps being taken. Such metrics can be collected on a management instrument called BSC (Balanced Scorecard). One can regularly take a look at those to make sure that deviations are caught before these turn awry enough to cause chaos.

One can sum it by stating that BSC has come up as an effectual strategy to count and measure the steps of any given process, JIT production being one of these.

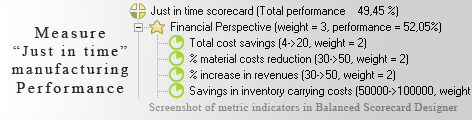

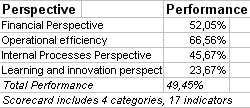

This is the actual scorecard with Just in time Dashboard and performance indicators. The performance indicators include: financial perspective, total cost savings, % material costs reduction, % increase in revenues, savings in inventory carrying costs, % decrease in scrap and re-work costs, operational efficiency, number of on-time deliveries, % decrease in scraps and reworks, % increase in productivity, first-pass yield rates, internal processes perspective, reduction in idle time, % manufacturing cycle time reduction, % increase in inventory turns, % reduction in supplier lead times, learning and innovation perspective, number of new/automated machines deployed, number of training sessions, number of process meetings of workforce, % reduction in new production introduction rate .

Download a trial version of Just in time Estimation Balanced Scoreboard or purchase a full version online.

How is this book different from 796 other book titles about KPIs on Amazon?

"Before writing a single line, I formulated some guiding principles, one of them was: "If our clients ask, "How can I find a good KPI for..." - I want this book to provide a perfect answer."