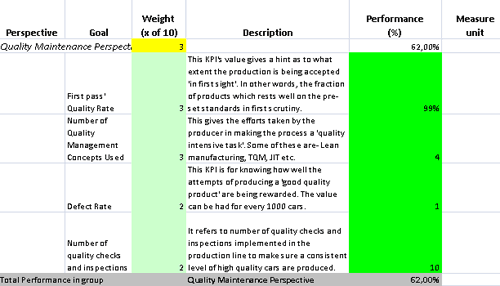

Car Manufacturing is a cumbersome task to carry out and an effective balanced scorecard that is reliable and accurate scorecard can go a long way in streamlining the manufacturing process.Apart from the actual and target values that are allotted to the parameters, the fact that these are to be 'maximized' or 'minimized' too goes to help in deciding 'which way to move'. One can increase overall production efficiency by following KPIs like number of units manufactured in one year, time consumed for production of one such unit, % decrease in per unit cost of production and knowing average production downtime. Quality can be embedded in the output by looking after parameters like number of quality management concepts utilized, defect rate, 'first pass' quality and number of quality checks and inspections. Internal processes can be prevented from going hay wire by tracking parameters such as number of hours worked on per employee basis, work related injuries, overall equipment effectiveness and % increase in car production rate. Issues pertaining to environment can be taken care of by relying on KPIs like 'volume of emission of volatile organic compounds', 'energy use that is needed for a single car production', 'waste to landfill' and 'water use'.

Car Manufacturing is a cumbersome task to carry out and an effective balanced scorecard that is reliable and accurate scorecard can go a long way in streamlining the manufacturing process.Apart from the actual and target values that are allotted to the parameters, the fact that these are to be 'maximized' or 'minimized' too goes to help in deciding 'which way to move'. One can increase overall production efficiency by following KPIs like number of units manufactured in one year, time consumed for production of one such unit, % decrease in per unit cost of production and knowing average production downtime. Quality can be embedded in the output by looking after parameters like number of quality management concepts utilized, defect rate, 'first pass' quality and number of quality checks and inspections. Internal processes can be prevented from going hay wire by tracking parameters such as number of hours worked on per employee basis, work related injuries, overall equipment effectiveness and % increase in car production rate. Issues pertaining to environment can be taken care of by relying on KPIs like 'volume of emission of volatile organic compounds', 'energy use that is needed for a single car production', 'waste to landfill' and 'water use'.

Read Why do business professionals choose ready-to-use KPIs? to find out the answers to these questions:

Ideally, you need to have a strategy (in a form of a strategy map) before you start thinking about the ways to measure its execution (KPIs). Don't have a strategy map yet? Use free Strategy Map Wizard to create a strategy map for your current business challenges. The wizard will:

The whole process takes on average 6 minutes. Give it a try right now - it's free.

It goes without saying that Car manufacturing is a cumbersome task owing to the uncountable aspects involved in it. Right from 'conceptualizing a design' to 'getting the vehicle out of the shop-floor' demands extreme detailing in every possible direction so as not to leave any room for improvement.

To start with, the huge investment that is required to run a car manufacturing facility makes for obvious reason to oversee the operations intelligently. Funds are required not only in 'vehicle production' but also for R&D purposes; the latter aim being more important tan the former at times. This is because a constant search for better and improved technology has to be kept on as this is what helps in 'towering above' the competitors in market.

Further, outsourcing of some of the 'ancillary' aspects is also often opted for by companies involved in car production. This leads to yet another 'fresh set' of areas that ask for attention as outsourcing is in itself a tricky job. Using the output that does not confirm to the guidelines pre-set by the outsourcer can lead to serious disturbances in the final product.

One of the ways by which these aspects can be pulled concurrently in 'vehicle manufacturing' is using a 'car manufacturing scorecard'. This strategy rests on turning the significant aspects into 'metrics' to be followed and tracked. This will impart transparency to the whole process, which is of immense value in a giant business that 'vehicle creation' is.

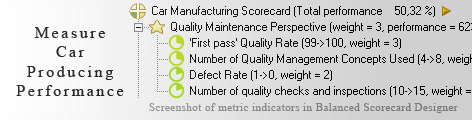

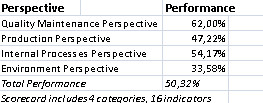

This is the actual scorecard with Car Manufacturing Measures and performance indicators. The performance indicators include: quality maintenance perspective, first pass quality rate, number of quality management concepts used, defect rate, number of quality checks and inspections, production perspective, % decrease in per unit cost of production, number of cars produced per year, average production time per car, average production downtime, internal processes perspective, number of hours worked per week, work related injuries, overall equipment effectiveness (oee), % increase in car production rate, environment perspective, volatile organic compounds (vocs), energy use, waste to landfill, water use.

Download a trial version of Car Manufacturing Estimation Balanced Scoreboard or purchase a full version online.

How is this book different from 796 other book titles about KPIs on Amazon?

"Before writing a single line, I formulated some guiding principles, one of them was: "If our clients ask, "How can I find a good KPI for..." - I want this book to provide a perfect answer."