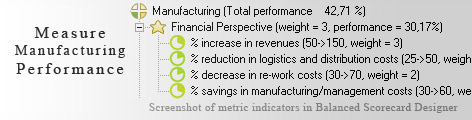

Development of a new product crosses three main stages: What to develop, how to develop and when to develop. Manufacturing process management tackles the -how to develop- stage more efficiently and effectively, the main objective being the reduction in product development cycle and costs to be incurred. It uses technologies and systems to achieve this objective. The KPIs can be classified into the following perspectives: Financial perspective comprises of KPIs that help in judging the various costs and savings in manufacturing operations. It includes KPIs like % savings in manufacturing and management costs, % increase in revenues, % decrease in logistics and distribution costs and % decrease in re-work costs.Customer perspective is a measure to determine the customer perception after the introduction manufacturing process management. The KPIs can be number of complaints, On-time deliveries, % increase in production yields and % improvement in cycle time.Internal process perspectives consist of KPIs such as % reduction in scraps/wastes, % decrease in idle time of machines and % increase in resource utilization and % improvement in labor productivity. This perspective helps in evaluating the effectiveness of systems and processes in reducing product cycle time and optimizing the costs.Innovation and growth perspective includes KPIs like number of technical training sessions, statistical process control tools, number of inter-group meetings and number of process knowledge initiatives. It refers to the new tools, processes and training provided to employees that guides and helps them to perform manufacturing processes in an efficient manner.

Development of a new product crosses three main stages: What to develop, how to develop and when to develop. Manufacturing process management tackles the -how to develop- stage more efficiently and effectively, the main objective being the reduction in product development cycle and costs to be incurred. It uses technologies and systems to achieve this objective. The KPIs can be classified into the following perspectives: Financial perspective comprises of KPIs that help in judging the various costs and savings in manufacturing operations. It includes KPIs like % savings in manufacturing and management costs, % increase in revenues, % decrease in logistics and distribution costs and % decrease in re-work costs.Customer perspective is a measure to determine the customer perception after the introduction manufacturing process management. The KPIs can be number of complaints, On-time deliveries, % increase in production yields and % improvement in cycle time.Internal process perspectives consist of KPIs such as % reduction in scraps/wastes, % decrease in idle time of machines and % increase in resource utilization and % improvement in labor productivity. This perspective helps in evaluating the effectiveness of systems and processes in reducing product cycle time and optimizing the costs.Innovation and growth perspective includes KPIs like number of technical training sessions, statistical process control tools, number of inter-group meetings and number of process knowledge initiatives. It refers to the new tools, processes and training provided to employees that guides and helps them to perform manufacturing processes in an efficient manner.

Read Why do business professionals choose ready-to-use KPIs? to find out the answers to these questions:

Ideally, you need to have a strategy (in a form of a strategy map) before you start thinking about the ways to measure its execution (KPIs). Don't have a strategy map yet? Use free Strategy Map Wizard to create a strategy map for your current business challenges. The wizard will:

The whole process takes on average 6 minutes. Give it a try right now - it's free.

Streamlining the manufacturing operations in any organization revolves around optimization of 'shop-floor operations'. To construct a useful and efficient assembly- line, one is required to impose a 'measurable' check on the operations. This further ensures that the act of production proceeds in the way it is 'intended to'.

Heading on, one can count the steps by packing some relevant and useful 'KPIs (Key Performance Indicators) in the form of Balanced Scorecard. This management strategy was devised in 1990s by Norton and Kaplan as financial metrics were found 'incomplete' to gauge a company's track. Consequently, 'non-financial indicators made their way into the scenario.

This act will assure the organization of being on a 'quantitative' path, thereby leading to construction of an effectual monitoring tool to gauge the generation process.

One is supposed to take the trouble of framing such a 'countable' management strategy as manufacturing constitutes the first stage in any series of product. This way, only if the most-initial step goes well that one can hope for the following ones to fall in place. The checks put during the manufacturing will go a long way in making things turn out the way they are 'supposed-to-be'.

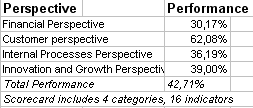

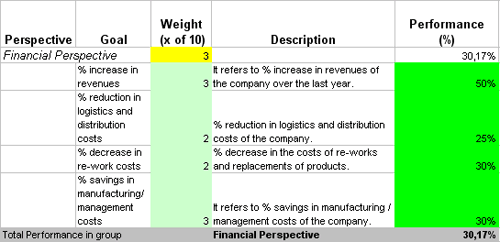

This is the actual scorecard with Manufacturing Performance Indicators and performance indicators. The performance indicators include: manufacturing, financial perspective, % increase in revenues, % reduction in logistics and distribution costs, % decrease in re-work costs, % savings in manufacturing/management costs, customer perspective, number of complaints, on-time deliveries, % increase in production yields, % improvement in cycle time, internal processes perspective, % reduction in scraps/waste, % decrease in idle time of machines, % increase in resource utilization, % improvement in labor productivity, innovation and growth perspective, number of technical training sessions, statistical process control (spc) tools, number of inter-group meetings, number of process knowledge initiatives .

Download a trial version of Manufacturing Evaluation Balanced Scorecard or purchase a full version online.

How is this book different from 796 other book titles about KPIs on Amazon?

"Before writing a single line, I formulated some guiding principles, one of them was: "If our clients ask, "How can I find a good KPI for..." - I want this book to provide a perfect answer."